BOSS has a vast selection of ice control equipment that will help you take on winter’s worst conditions. Along with this, there is a selection of accessories that you can purchase to upgrade your spreaders so that they can work for any job you take on. Click here to learn more about the accessories you can use to upgrade your equipment.

If you’re researching electric v-box hopper spreaders, you are learning quickly that the two types of material feed systems available are the auger and pintle chain. If you don’t have a lot of experience with these spreader feed systems, you may be having a difficult time selecting which system best fits your snow and ice management needs. BOSS offers a pintle or auger feed system on the VBX and FORGE line of spreaders. There are some key differences between the two feed systems that are important to understand. Read on to learn more about auger and pintle spreaders to help you decide which spreader is right for you.

Regional Preferences

In general, in the United States, auger feed systems tend to be more popular in the Midwest and Ohio Valley areas. Pintle chains are the preferred feed system in the New England region. It’s hard to say why but perhaps familiarity with previous v-box hopper spreading systems or agricultural products has led to the regional spreader feed system preferences.

Auger Spreaders

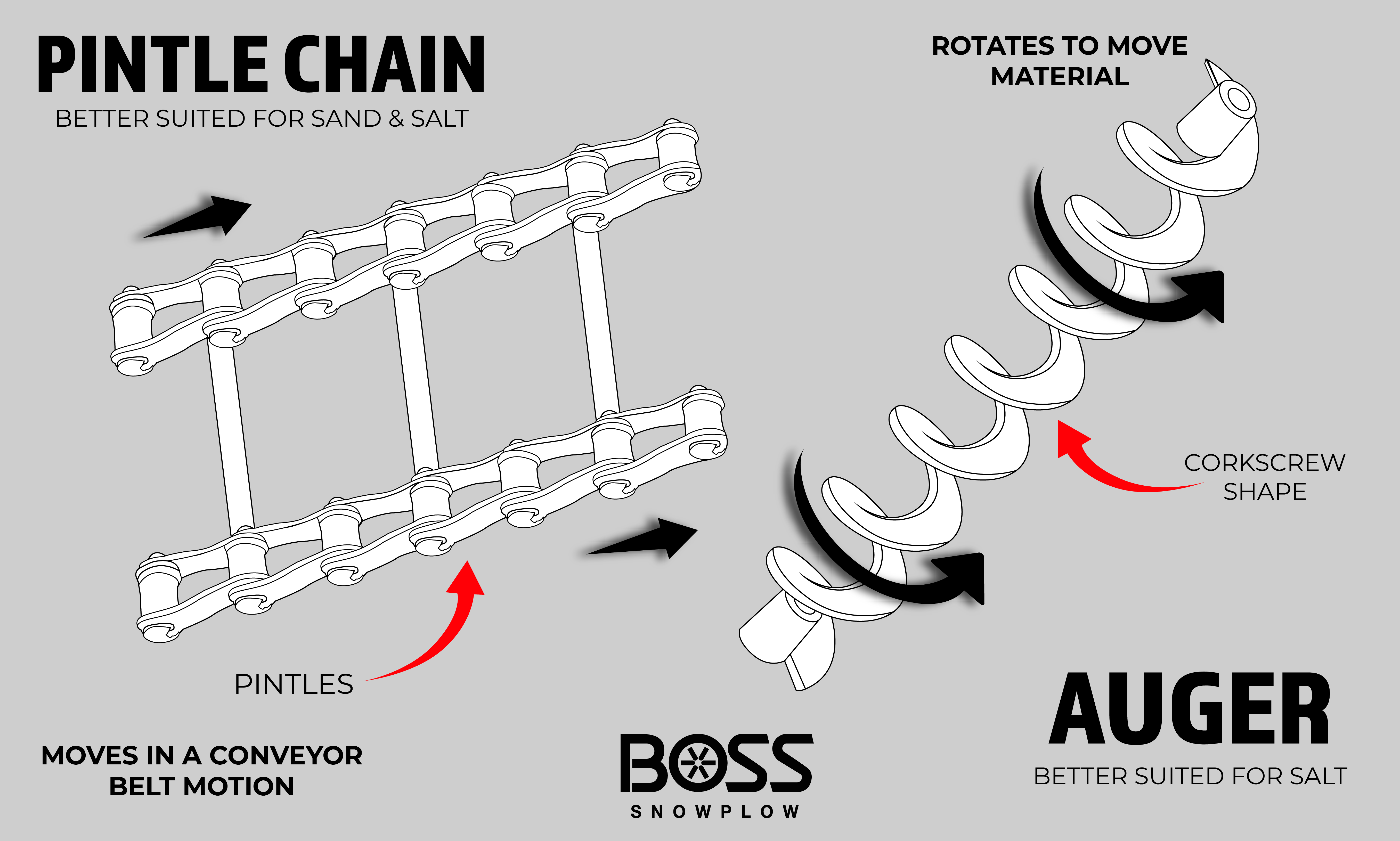

Among the auger’s greatest advantages over the pintle system is that it has fewer moving parts and no chains to maintain. This means that it requires less maintenance over time. It has a simple steel auger with flighting that “pulls” the salt and sand material towards the discharge chute. The even pulling of the material by the auger allows the auger feed system to have a more “even” flow of material, and as a result, the spread pattern coming off the spreader tends to be more even than it does with a pintle chain system. The auger, shaped like a corkscrew, spins to spread particulates at around 2.3 cubic feet per minute, this means it is better suited to drier, free flowing material like salt.

The auger system also has the capability to break up chunks of salt and sand that sometimes form inside the hopper – the auger can in fact “crush” those clumps and allow them to be processed and spread. Many of auger spreaders have a feature that protects the auger motor from being overloaded by materials that jam the auger. The system will sense the jam and cause the auger to move in reverse and forward a couple of times to clear the jam. If the object is not cleared – the controller will indicate a jam has occurred, allowing the operator to clear the jam and save the auger motor from serious damage. Most auger system v-box spreaders utilize vibrators to keep the material in the hopper loose enough to flow to the feed system. However, even the best vibration system in the world cannot overcome material that has frozen into a solid clump because of moisture or water intrusion. It is very important for the operator of the spreader to try to keep the spreading material as dry as possible, and ideally, not allow a filled hopper to sit for extended periods of time in very cold weather as “bridging” can occur. Bridging happens when the material freezes into a solid mass, no longer flowing into the feed system, creating a solid “bridge” of material over the top of the feed system much like a bridge over a flowing river.

To lessen the weight load of the material on the auger, most auger hoppers utilize inverted “v” baffles. These baffles help to control the weight and flow of the material onto the auger. If the weight on the auger is too great at startup – the motor could get damaged. Typically, upgrading your spreader with a vibrator kit will help shake the salt and agitate it to keep a constant flow around any material obstructions.

Pintle Spreaders

Pintle spreaders are an optional upgrade onto your VBX and FORGE spreaders at the time of purchase. However, the VBX 3000 spreader features the auger only. The pintle auger is comprised of more moving parts than the auger. The pintle features a chain with a pivot point on each link. It also features two rotating shafts, bearings, sprockets, and tensioning devices. With more moving parts, the pintle spreader may need regular maintenance to keep running properly. However, they are less susceptible to jamming and damage from rock or obstructions when spreading sand. The pintle chain system utilizes a flat, 12” wide (BOSS) pintle chain which acts like a conveyor belt feeding material from the hopper to the discharge chute and spinner assembly. The large surface area of the pintle chain allows the system to carry more material to the discharge chute than the auger, especially when set at “Max Flow” settings.

Pintle spreaders are a lot more versatile with what materials they can dispense. Unlike auger spreaders, pintle spreaders are better suited to spread wetter material like sand. They can also spread other materials like salt, and sand/salt combinations. Many pintle chain systems also use inverted v baffles as well – although they may not always be needed with this feed system. Because the pintle chain system is metallic and exposed to highly corrosive materials like salt, the need for maintaining the chain links, etc, is greater than it is for the auger feed system.

Carefully consider the specifications of each before purchasing. For instance, the difference between the BOSS Snowplow feed systems:

Auger Flow Rate at MAX Setting |

Pintle Flow Rate at MAX Setting |

| 2.3 cu ft (0.06 cu m) per minute | 4 cu ft (0.11 cu m) per minute |

Pro’s & Con’s Wrap Up

Auger Feed System

Pros:

- Fewer moving parts

- More even flow of materials

- More even spreading pattern

Cons:

-

Less maximum material flow for spreading

-

Material with rocks in it could cause jamming

Pintle Chain Feed System

Pros:

- More maximum material flow for spreading

- Less potential for jamming

Cons:

-

Less even material feeding than auger

-

Less even spread pattern than auger

-

Pintle Chain maintenance

Spreader Maintenance

Proper maintenance on both spreaders will help the longevity of the hopper and spreader. Grease the connections using a dielectric grease, applying only a light film. Being sure not to pack the connections with grease, using a contact cleaner to clean out connector areas with hardened grease will help to keep your spreader in shape. For VBX and Forge auger spreaders, you should grease the bearings on the unit every 20 hours of use. For pintle spreaders, the chain should also be greased every 20 hours of use. When storing a VBX or Forge unit with a pintle spreader, you should spray the chain with WD40 or PB Blaster to force out any remaining salt left behind.

Properly installing the main side harness is also an important step in regular spreader maintenance. Make sure the connector ends are adequately supported without hanging down in any way. When the harness unit is not installed, be sure to use dust and weather caps on the connections to protect it from any vulnerability that may occur.

Water should not be used to clean out your unit regularly. This will push salt water into all connections, drive assemblies, and gearboxes. Doing this will lead to rust corrosion and reduce the longevity of your spreader. Your unit should only be washed out and then blown out or air dried at the end of each season.

Learn more about the BOSS hopper spreaders by visiting www.bossplow.com/products