Let’s face it snow plows are bound to encounter obstacles. Those obstacles could include manhole covers, curbs, frozen snow banks and everything in between. If you have been snowplowing for any period of time, you could probably add a few other items to that list. Obstructions and obstacles are one of the unavoidable dangers of snowplowing. As such, snow plow manufacturers design and build snow plows with trip protection technology to help protect the plow and truck from damage. The tripping mechanism works in tandem with the snow plow’s pressure relief valves that are also designed to reduce the impact caused by obstructions. BOSS Snowplows, including the BOSS XT & DXT, are specifically designed with one of three types of tripping systems:

-

Trip-Edge Snow Plow: Plows designed with a trip-edge will help reduce the impact on your plow should you hit an obstacle smaller than 6 inches high, these are commonly man-hole covers or large cracks in the pavement. When the trip-edge base angle hits these hidden obstructions, the base angle/edge of the plow trips backwards to “give way” to the object. This takes some of the force off of the entire plow, which means less impact to the plow itself, the front of your truck, and to you, the operator. An example of a trip-edge snow plow is the BOSS Trip-Edge Super-Duty straight blade.

-

Full-Moldboard Trip Snow Plow: With a full-moldboard trip snowplow, should you hit an object taller than 6 inches, the entire moldboard trips forward to cushion the impact. This greatly reduces the force on the plow and truck and helps keep you and your equipment safe. An example of a full-moldboard trip snow plow is the BOSS XT v-plow or the BOSS Super-Duty straight blade.

-

Dual-Trip Snow Plow: A plow with dual-trip protection has just what the name implies – two tripping systems. In the case of a BOSS DXT snowplow, the plow is designed with both the trip-edge as well as the full-moldboard trip creating dual-trip protection.

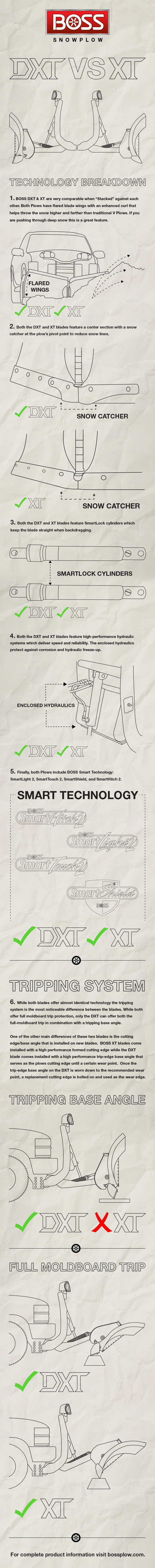

As noted and reviewed above, BOSS manufactures two models of v-plows, the XT & the DXT each featuring a different trip design. The XT V-blade is designed with a full-moldboard trip and the DXT v-blade with dual-trip protection. One of the other main differences of these two blades is the cutting edge/base angle that is installed on new blades. BOSS XT blades come installed with a high performance formed cutting edge while the DXT blade comes installed with a high performance trip-edge base angle that serves as the plows cutting edge until a certain wear point. Once the trip-edge base angle on the DXT is worn down to the recommended wear point, a replacement cutting edge is bolted on and used as the wear edge. In summary, the tripping mechanism and the wear edge are the main differences between the XT & DXT. For a complete comparison you can view the product specification sheets: XT | DXT. In addition, the following video and infographic visually represents the differences between the two snowplows.