Introduction:

Liquids are the future of snow and ice management. Offering much better consistency, accuracy, and adaptability and provides the best avenue for the future of mandatory chloride-free deicing. Many new sites around the US and Canada are already setting chloride reduction and chloride-free standards. It’s not a question of if. It’s a question of when. Don’t get left behind!

Liquid Deicing:

There is almost a 2:1 ratio in the cost of using salt vs. liquids. Our experience has seen a typical 3:1 ratio for labor expense of applying salt vs. liquids. That means for every man-hour of labor with a liquid sprayer, you can apply 3 times the acreage that you can with a salt spreader. This is due to faster and more efficient reloading, more acres of coverage before a refill than a salt truck, more consistency in the application (less overlap, overapplication) etc.

One other financial savings metric to remember is residual liquids left on well “seasoned” lots and pre-treated lots. These residual savings mean your salt on a post-application will require 50-60% less than untreated lots. So even if you elected not to use post-treatment with liquid, the savings of ½ or more of your typical salt application would amount to a savings of at least $5,100 per full event in the 200-acre hypothetical scenario, just by pre-treating and seasoning your lots with liquids. Even larger savings exist when using liquids on sidewalks at an 80/20 blend vs. bagged ice melt product slicer.

** Comparing liquid blends with treated salt would be a more even comparison, but since there is some labor involved in blending the white salt into the brine, we left out the comparison with white salt. **

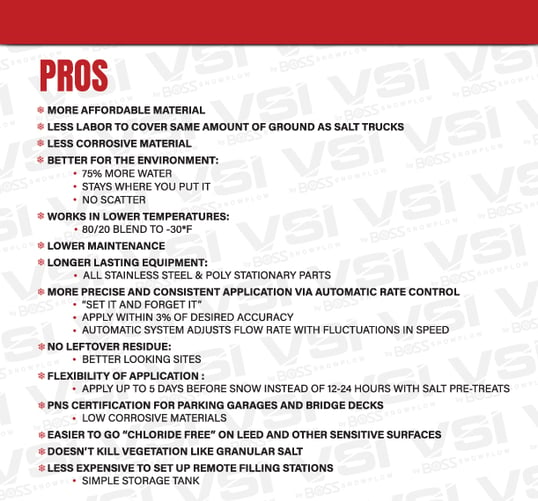

Pros of Liquid Deicing:

Cons of Liquid Deicing:

VSI Example:

Many of our clients who have implemented more liquids had concerns about converting customers and sites away from rock salt as that is what the customers are used to and “used to seeing salt on the lots.” Change of any type poses challenges, even when the change is good. The results have been universally positive, cleaner sites and lots, little to no tracking, reduced janitorial costs for the client, faster melting of ice and snow, and all of the other aforementioned benefits.

In our commercial snow and ice operation 11 years ago, we gave customers the choice to continue using conventional rock salt or switch over to liquid. At first, 80% of customers elected to stick with what they knew (granular product), and the other 20% told us to use what we thought was best. One year later, we made a mass conversion over to liquid only. A few clients remained skeptical but later demanded we use nothing but liquids on their sites after seeing the results and cleanliness of the applications. Four years into our liquid conversion we had an ice storm in which we had some equipment failure, so we were forced to use some calcium chloride pellets on the sidewalks to get things ready for opening hours. We received multiple complaint phone calls that day asking why we returned to using granular products on their sites. A full 180 from hesitancy and concern, to sheer demand that we only use liquid products on their sites. And, as we can see, the pros most definitely outweigh the cons.