As anyone in snow and ice management knows, the selection of deicing material and equipment can be complicated and varies greatly by personal preferences and experiences. For those new to the industry finding straightforward answers to basic questions regarding the use of deicers can be somewhat of a challenge.There is much debate about what materials to spread and which equipment to use. If you find yourself needing assistance when choosing spreading materials, use this blog and infographic to help find the right equipment, and more importantly, the proper type of deicing material you should be filling that equipment with.

There are three main categories of deicing material: fine deicers, coarse deicers and sand/crushed rock. Let’s take a closer look at the type of materials recommended for tailgate and hopper spreader use.

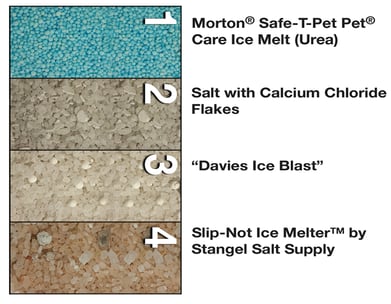

Fine Deicing Materials (1-4):

Fine deicing materials are deicers that have tiny granules. They generally come in smaller bags or 5 gallon pails and they tend to be more expensive than bulk ice control materials. If you are using fine deicing materials, a small capacity tailgate spreader, like the BOSS TGS 300 would be recommended. The BOSS TGS 300 comes standard with a material saver system that is engineered to capture fine deicing material when the spreader is not in use thus reducing material waste. If you desire to run a coarse material, like bulk salt, in this small capacity spreader, you will need to convert the standard material saver system to the higher output material system that is standard in the BOSS TGS 600 and 1100 tailgate spreader. Without this conversion, the coarse material will have a tendancy to become clogged in the spreader. To make this conversion, three BOSS parts are needed:

Fine deicing materials are deicers that have tiny granules. They generally come in smaller bags or 5 gallon pails and they tend to be more expensive than bulk ice control materials. If you are using fine deicing materials, a small capacity tailgate spreader, like the BOSS TGS 300 would be recommended. The BOSS TGS 300 comes standard with a material saver system that is engineered to capture fine deicing material when the spreader is not in use thus reducing material waste. If you desire to run a coarse material, like bulk salt, in this small capacity spreader, you will need to convert the standard material saver system to the higher output material system that is standard in the BOSS TGS 600 and 1100 tailgate spreader. Without this conversion, the coarse material will have a tendancy to become clogged in the spreader. To make this conversion, three BOSS parts are needed:

TGS05882 - Auger with cable assembly

TGS05892 - Rotary Actuator Shaft

TGS10984 - Feed gate kit

.

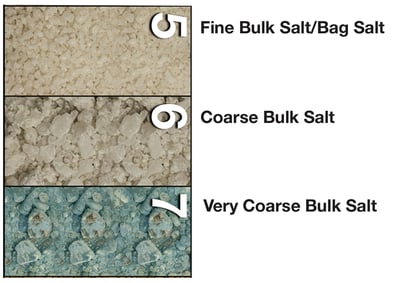

Coarse Materials (5, 6, 7):

Coarse deicing materials are deicers that have larger granules. They are generally less expensive than a fine deicer and can be purchased in larger quantities. If you have several snow and ice management accounts that require deicing, you will most likely need a higher capacity spreader and may also have the need to purchase deicers in bulk.

Coarse deicing materials are deicers that have larger granules. They are generally less expensive than a fine deicer and can be purchased in larger quantities. If you have several snow and ice management accounts that require deicing, you will most likely need a higher capacity spreader and may also have the need to purchase deicers in bulk.

The BOSS TGS 600 and 1100 tailgate spreaders are ideal for spreading these coarse material types. You can also use the TGS 800 tailgate spreader or a VBX8000 hopper spreader with either an auger or pintle chain. Any of these spreader options can handle coarse materials. However, the TGS 800 spreader was designed primarily for sand use and the material distribution is high in comparson to the 600 or 1100. If you are primarily using salt based materials you may want to opt for the TGS 600 or 1100 over the TGS 800 for a more economical spread pattern.

With several spreader options in this category, determining your capacity needs will aid in determining if you will need a tailgate or a hopper spreader.

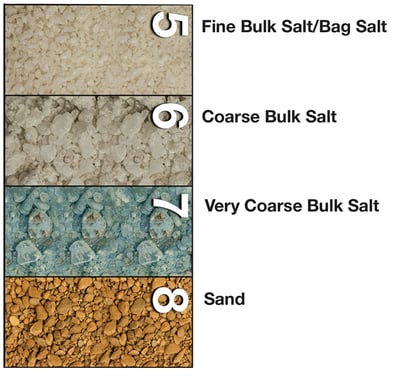

Sand and Bulk Salt (5-8):

When using sand as a deicing material, you have to be very careful and make sure you know for certain that your spreader it is designed to spread this material type. Sand is prone to moisture and bridges more easily than other materials and because of this you may experience restricted material flow in comparison to other deicing materials. Both the BOSS TGS 800 and Pintle Chain VBX 8000 are up for the task of spreading sand. If your capacity needs lead you towards a hopper spreader and you wish to run sand, a pintle chain is the most ideal system for sand and materials that are prone to moisture. However, if you desire to use a hopper spreader with an auger, you’ll need to use a vibrator kit to aid in material flow. The vibrator kit comes standard on the BOSS auger hopper spreaders. You’ll also want to raise the inverted V baffle all the way up to allow material to flow down.

When using sand as a deicing material, you have to be very careful and make sure you know for certain that your spreader it is designed to spread this material type. Sand is prone to moisture and bridges more easily than other materials and because of this you may experience restricted material flow in comparison to other deicing materials. Both the BOSS TGS 800 and Pintle Chain VBX 8000 are up for the task of spreading sand. If your capacity needs lead you towards a hopper spreader and you wish to run sand, a pintle chain is the most ideal system for sand and materials that are prone to moisture. However, if you desire to use a hopper spreader with an auger, you’ll need to use a vibrator kit to aid in material flow. The vibrator kit comes standard on the BOSS auger hopper spreaders. You’ll also want to raise the inverted V baffle all the way up to allow material to flow down.

Use the infographic below as a visual reference to remember which type of materials specifically should be loaded into tailgate and hopper type spreaders. Remember, the selection of proper deicing materials can be complicated and vary by personal preference, experience and environmental concerns and all factors should be considered before making your selection.

If you have any further questions visit the BOSS technical service page or give our service team a call at 800-286-4155 ext. 2.