HOPPER SPREADER SYSTEMS

Auger or Pintle Chain | Which hopper spreader system is right for you?

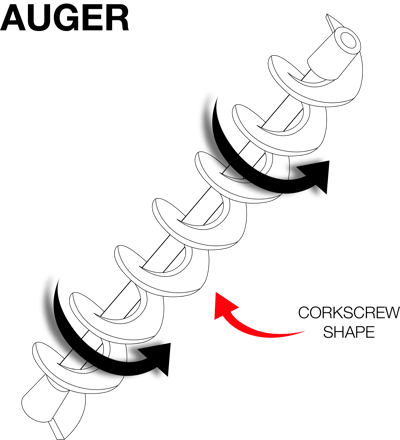

BOSS Auger System

The auger in your BOSS hopper spreader is a crucial component. It is designed with a screw-like mechanism resembling a corkscrew. Its primary function is consistently and effectively moving and spreading particulate materials, such as salt or sand, ensuring optimal distribution and coverage.

Easy to Maintain & Reliable

Designed with fewer parts, the auger system requires less maintenance and is less likely to jam. In the rare event of a jam, it automatically moves back and forth to clear the blockage, with an indicator light on the controller to notify you if assistance is needed.

Efficient Material Dispersion

Utilizes a corkscrew shape to disperse particulates rapidly at approximately 2.3 cubic feet per minute, making it ideal for dry, free-flowing materials such as salt.

Effective Clump Breakdown

Effectively breaks down salt and sand chunks that may accumulate inside the hopper, ensuring uninterrupted performance.

How It Works

The steel auger "pulls" material toward the discharge chute, allowing the feed system to distribute a more even flow of materials.

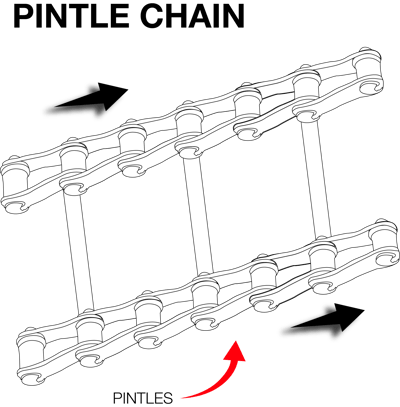

BOSS Pintle Chain System

Pintle chain systems are an optional upgrade onto your VBX and VBX+ spreaders at the time of purchase. The Pintle Chain model boasts a chain with pivoting links, along with dual rotating shafts, precision bearings, sprockets, and efficient tensioning devices. Please note, the VBX 3000 spreader features the auger only.

Enhanced Performance

Increases maximum material flow for efficient spreading and enhances versatility, handling various materials.

Improved Reliability

Minimizes the potential for jamming, ensuring continuous operation and reliable performance.

Versatile Material Distribution

This system utilizes a conveyor belt shape to efficiently spread particulates at around 4 cubic feet per minute, making it ideal for distributing wetter materials like sand. It excels in spreading a variety of materials including sand, salt, and sand/salt combinations, adapting seamlessly to diverse application needs.

How It Works

The pintle chain utilizes a flat 12" wide pintle chain, which includes links with pivot points, as a conveyor belt. This design efficiently feeds material from the hopper to the discharge chute and spinner, ensuring smooth operation and consistent distribution.